MFC-2700DW Manual: A Comprehensive Guide

This manual provides detailed instructions for the Brother MFC-2700DW, covering setup, operation, troubleshooting, and maintenance. It’s a resource for all users, ensuring optimal performance.

Welcome to the world of efficient document management with the Brother MFC-2700DW! This multifunction center (MFC) is designed to streamline your workflow, offering printing, scanning, copying, and faxing capabilities in a single, compact device. It’s a versatile solution for home offices and small businesses alike.

The MFC-2700DW builds upon decades of Brother’s commitment to reliability and innovation. While frameworks like MFC (Microsoft Foundation Classes) have evolved over time, the core principle remains – simplifying complex tasks. Like early C with classes approaches, this MFC aims to provide a user-friendly experience. This manual will guide you through every aspect of your new printer, from initial setup and driver installation to advanced features like duplex printing and mobile connectivity via solutions like Brother iPrint&Scan.

We’ll also address common issues, such as paper jams and toner-related messages, ensuring you can quickly resolve any problems. Consider this manual your essential companion for maximizing the potential of your MFC-2700DW.

Understanding the MFC-2700DW’s Core Features

The Brother MFC-2700DW boasts a robust set of features designed for productivity. At its heart, it’s a versatile device, much like the evolution from basic C programming to object-oriented approaches with frameworks like MFC – simplifying complex processes. It excels in monochrome laser printing, delivering crisp, professional-quality documents.

Key features include automatic duplex printing (two-sided printing), saving paper and reducing costs. Wireless connectivity (Wi-Fi and Ethernet) allows for seamless integration into your existing network, enabling mobile printing through Brother’s iPrint&Scan app. The intuitive control panel and menu system provide easy navigation and control.

Scanning and copying functions offer high-resolution results, suitable for archiving or reproducing documents. While not a modern framework like Qt, the MFC-2700DW provides essential functionality. It’s a reliable workhorse, offering a balance of performance and affordability, even if it doesn’t match the speed of newer technologies.

Setting Up Your MFC-2700DW

Begin with unboxing, driver installation, and network connection (Wi-Fi or Ethernet). Proper setup ensures seamless operation and access to all features of your printer.

Unboxing and Initial Setup

Carefully unpack your Brother MFC-2700DW, ensuring all components are present. These typically include the printer itself, power cord, telephone line (if applicable), a starter toner cartridge, and essential documentation like the quick setup guide and safety instructions. Remove all protective tape and packaging materials, both inside and outside the printer.

Place the MFC-2700DW on a stable, level surface with adequate ventilation. Connect the power cord to the printer and a grounded electrical outlet. Avoid placing the printer in direct sunlight or near sources of heat or moisture. Before proceeding, verify that the printer’s power switch is in the “OFF” position. Initial setup involves selecting your language, country, and date/time settings via the control panel. Follow the on-screen prompts to complete this process. This foundational step prepares the printer for driver and software installation.

Installing Drivers and Software

To unlock the full potential of your Brother MFC-2700DW, installing the correct drivers and software is crucial. The easiest method is using the installation disc included in the box. Insert the disc into your computer and follow the on-screen instructions. Alternatively, download the latest drivers and software package directly from the official Brother support website.

During installation, choose between a standard or custom installation. A standard installation installs the essential printing and scanning functionalities. A custom installation allows you to select specific components, such as network connectivity features. Ensure your computer is connected to the internet during the installation process to automatically download any necessary updates. Once installed, restart your computer to finalize the setup. Verify successful installation by attempting a test print.

Connecting to Your Network (Wi-Fi & Ethernet)

The Brother MFC-2700DW offers flexible connectivity options – Wi-Fi and Ethernet – to seamlessly integrate into your existing network. For Wi-Fi setup, access the machine’s menu via the control panel. Navigate to Network settings, then Wireless LAN setup. Select your network name (SSID) from the list and enter the correct password.

For a wired Ethernet connection, simply connect an Ethernet cable from the MFC-2700DW to your router or network switch. The machine will automatically obtain an IP address. Confirm the connection by printing a network configuration page from the machine’s menu. Successful network connectivity enables features like mobile printing and remote access. Ensure your firewall settings allow communication with the printer for optimal functionality.

Operating the MFC-2700DW

This section details the MFC-2700DW’s operation, including the control panel, menu navigation, and core functions like printing, scanning, and copying for efficient use.

Control Panel Overview

The Brother MFC-2700DW features an intuitive control panel designed for ease of use. At the center is a color touchscreen display, providing clear visual feedback and access to all primary functions. Below the touchscreen, you’ll find physical buttons for frequently used actions like Stop, Back, and Start.

The touchscreen interface is context-sensitive, meaning the options displayed change based on the selected function. Icons are used extensively for quick identification of features such as printing, scanning, copying, and faxing (if applicable). A dedicated numeric keypad simplifies entering fax numbers or selecting document quantities.

Navigating the control panel is straightforward; simply tap the desired icon or option on the touchscreen. The physical buttons offer a tactile alternative for common commands. The panel also displays status information, including toner levels, paper supply, and any error messages that may occur. Familiarizing yourself with the layout will significantly streamline your workflow and enhance your overall experience with the MFC-2700DW.

Navigating the Menu System

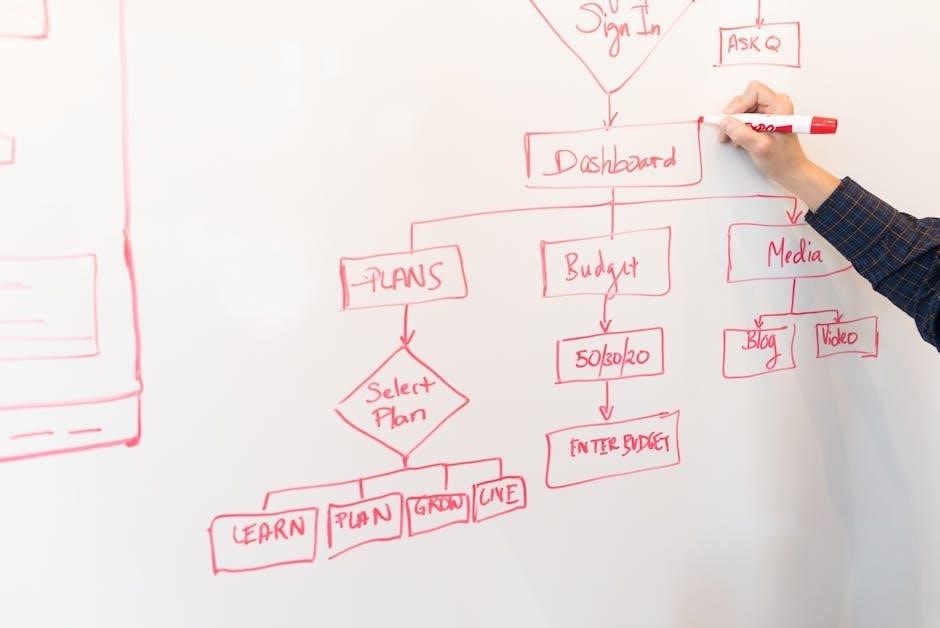

The MFC-2700DW’s menu system is accessed via the color touchscreen on the control panel. Tapping the “Menu” icon reveals a hierarchical structure of settings and options. Use the up and down arrow icons to scroll through the main menu categories, such as “Print,” “Scan,” “Copy,” “Fax,” and “Setup.”

Selecting a category drills down into submenus with more specific settings. Within each submenu, you can adjust parameters like paper size, print quality, scan resolution, and network configurations. The “OK” button confirms your selections, while the “Back” button returns you to the previous menu.

The menu system also includes a search function, allowing you to quickly locate specific settings by keyword. Pay attention to on-screen prompts and help messages, which provide guidance and explanations for each option. Regularly exploring the menu system will unlock the full potential of your MFC-2700DW and allow you to customize it to your exact needs.

Basic Printing Operations

To initiate a print job, ensure the MFC-2700DW is powered on and connected to your computer. Open the document you wish to print from your application. Select “Print” from the File menu, and choose “Brother MFC-2700DW” as your printer.

The Brother print driver window will appear, offering various printing options. Adjust settings like paper size, print quality (Normal, Fine, Best), and the number of copies. You can also select duplex printing (two-sided) to save paper. Click “Print” to send the job to the printer.

The MFC-2700DW will automatically detect the paper type and adjust settings accordingly. Monitor the printer’s status on the touchscreen to confirm the print job is processing. For optimal results, use recommended paper types and ensure the paper tray is properly loaded. Basic printing is now complete!

Scanning and Copying Procedures

To scan a document, place it face down on the scanner glass. From the MFC-2700DW’s control panel, select the “Scan” function. Choose your desired scan settings: resolution (300dpi is standard), file type (PDF, JPEG), and destination (computer, email). Press the “Start Scan” button to begin the process.

For copying, place the original document on the scanner glass. Select the “Copy” function on the control panel. Adjust copy settings like darkness, number of copies, and paper size. The MFC-2700DW will automatically scan and print the copy.

Both scanning and copying can be initiated directly from the machine or through the Brother software on your computer. Ensure the document is properly aligned for optimal results. The machine supports both color and black & white scanning/copying.

Advanced Features and Troubleshooting

Explore duplex printing, mobile solutions like Brother iPrint&Scan, and solutions for paper jams and print quality. Resolve toner issues efficiently with this guide.

Duplex Printing (Two-Sided Printing)

The MFC-2700DW offers convenient duplex printing, saving paper and reducing costs. To enable this feature, access the printer settings through the control panel or your computer. Within the print dialog box, locate the “Duplex Printing” option and select it. Ensure the paper is appropriate for two-sided printing – standard weight paper is generally recommended.

For optimal results, verify the paper type setting matches your chosen paper. The MFC-2700DW automatically flips the paper for printing on both sides; You can typically choose between long-edge binding (like a book) or short-edge binding (like a notepad). Experiment to determine which setting best suits your document.

If duplex printing isn’t functioning correctly, check for paper jams and ensure the paper tray is properly loaded. Incorrect paper settings or damaged paper can also cause issues. Refer to the troubleshooting section for further assistance if problems persist.

Mobile Printing Solutions (Brother iPrint&Scan)

The Brother iPrint&Scan app extends the MFC-2700DW’s functionality to your mobile devices. Available for iOS and Android, this application allows you to print directly from your smartphone or tablet without needing a computer. It also enables scanning documents to your mobile device for easy sharing and storage.

To begin, download and install the iPrint&Scan app from your device’s app store. Ensure your MFC-2700DW is connected to the same Wi-Fi network as your mobile device. The app will automatically detect your printer. Follow the on-screen instructions to complete the setup process.

With iPrint&Scan, you can print various file types, including documents, photos, and web pages. You can also adjust print settings, such as paper size and quality, directly from the app. Scanning is equally straightforward, offering options for saving files in PDF or image formats.

Resolving Common Paper Jams

Paper jams are a frequent issue, but easily resolved with careful steps. First, power off the MFC-2700DW and disconnect it from the power source for safety. Locate the access panels – typically at the rear, front, and inside the machine. Gently remove any visible jammed paper, pulling in the direction of the paper path. Avoid tearing the paper, as fragments can cause further issues.

Inspect all areas thoroughly, including the paper tray and duplex unit (if applicable). Use a flashlight to illuminate dark corners. If paper is stuck in a difficult-to-reach area, consult the detailed diagrams in the full manual. Once all paper fragments are removed, close all access panels securely.

Reconnect the power and turn the MFC-2700DW back on. Run a test print to confirm the jam has been cleared. Prevent future jams by using recommended paper types and ensuring the paper tray isn’t overfilled.

Troubleshooting Print Quality Issues

Poor print quality can stem from several causes. First, check the toner cartridge – a low or empty cartridge will produce faded prints. Replace it if necessary. Next, examine the printed page for specific issues: streaks, smudges, or missing sections. Streaks often indicate a dirty drum unit; clean it using the appropriate procedure outlined in the manual.

Smudges can result from incorrect paper type or humidity. Ensure you’re using Brother-recommended paper. Adjust print density settings within the printer driver for darker or lighter output. For missing sections, run the print head cleaning utility from the printer’s control panel or the Brother software suite.

Finally, verify the paper path is clear of obstructions. A damaged drum unit or fuser may require professional servicing. Regularly maintaining your MFC-2700DW will prevent many quality issues.

Addressing “Toner Low” or “Toner Empty” Messages

Receiving a “Toner Low” or “Toner Empty” message doesn’t always mean immediate replacement is needed. Sometimes, the sensor may be malfunctioning. Gently remove and reinstall the toner cartridge; this can reset the sensor. However, if the message persists, it’s likely time for a new cartridge.

Before replacing, confirm you’re using a genuine Brother toner cartridge to ensure compatibility and optimal print quality. Avoid refilled or third-party cartridges, as they may cause damage or poor performance. After installing a new cartridge, perform a toner reset via the printer’s menu – navigate to ‘Device Info’ and select ‘Toner Reset’.

If the issue continues after resetting, consult the Brother support website or contact their customer service for further assistance. Ignoring these messages can lead to diminished print quality and potential printer damage.

Maintenance and Support

Regular cleaning, firmware updates, and proper toner replacement are crucial for longevity. Brother provides extensive online resources and dedicated support channels for assistance.

Replacing the Toner Cartridge

Replacing the toner cartridge in your Brother MFC-2700DW is a straightforward process, ensuring continued high-quality printing. First, ensure the machine is powered on. Open the front cover of the printer – you’ll find it easily located on the front panel. Carefully remove the used toner cartridge and its protective cover.

Unpack the new toner cartridge, and gently remove any protective seals or tape. Align the new cartridge with the guides inside the printer and slide it firmly into place until it clicks. Replace the protective cover over the new cartridge. Finally, close the front cover of the printer.

The MFC-2700DW may automatically detect the new cartridge; if not, navigate to the menu and manually confirm the replacement. Always dispose of used toner cartridges responsibly, following local regulations for electronic waste.

Cleaning the MFC-2700DW

Regular cleaning of your Brother MFC-2700DW is crucial for maintaining optimal print quality and extending the machine’s lifespan. Begin by powering off the printer and disconnecting it from the power source for safety. Use a soft, lint-free cloth to gently wipe down the exterior surfaces, removing dust and smudges.

For internal cleaning, carefully open the front cover and use a dry cloth to wipe the inside, paying attention to the paper path; Avoid using liquids or abrasive cleaners, as these can damage the components. The scanner glass should be cleaned with a specialized glass cleaner, applied to the cloth, not directly onto the glass.

Periodically, run the cleaning function through the printer’s menu to remove any accumulated toner dust. Proper cleaning ensures consistent performance and prevents potential print quality issues.

Updating Firmware

Keeping your Brother MFC-2700DW’s firmware up-to-date is essential for optimal performance, security enhancements, and compatibility with new features. Firmware updates address bugs, improve stability, and often add support for the latest operating systems and printing protocols.

To update the firmware, first, visit the official Brother support website and download the latest firmware version specifically for your MFC-2700DW model. You’ll typically have the option to update via USB or network connection.

For USB updates, follow the on-screen instructions to transfer the file to the printer. Network updates require the printer to be connected to your Wi-Fi or Ethernet network. During the update process, do not power off the printer or interrupt the connection, as this could cause irreversible damage.

Contacting Brother Support

If you encounter issues not addressed in this manual, Brother offers several support channels to assist you. Their official website (support.brother.com) is a valuable resource, providing FAQs, troubleshooting guides, and downloadable drivers.

You can also reach Brother Support via telephone. Support numbers vary by region, so consult the Brother website for the correct contact information for your location. Live chat support is often available, offering real-time assistance from a support representative.

When contacting support, have your MFC-2700DW model number and serial number readily available. Clearly describe the issue you are experiencing, including any error messages displayed. Providing detailed information will help the support team diagnose and resolve your problem efficiently. Brother also offers online communities and forums where users can share solutions and advice.

Technical Specifications

This section details the MFC-2700DW’s key technical attributes, including print speed, resolution, paper capacity, connectivity, and physical dimensions for comprehensive understanding.

Print Speed and Resolution

The Brother MFC-2700DW boasts impressive print speeds for both monochrome and color documents. Expect up to 32 pages per minute (ppm) for monochrome printing, ensuring efficient output for everyday tasks. Color print speeds reach up to 30 ppm, delivering vibrant and detailed results. This printer excels in producing high-quality documents, thanks to its maximum print resolution of 600 x 600 dpi.

This resolution ensures sharp text and clear images, ideal for professional reports, presentations, and marketing materials. The MFC-2700DW utilizes laser technology, contributing to its speed and precision. Furthermore, the printer supports various paper types and sizes, accommodating diverse printing needs. Automatic duplex printing further enhances productivity by allowing you to print on both sides of the paper simultaneously, reducing paper consumption and costs. The combination of speed and resolution makes the MFC-2700DW a versatile printing solution.

Paper Handling Capabilities

The Brother MFC-2700DW offers versatile paper handling, accommodating a wide range of media types and sizes. Its standard paper tray holds up to 250 sheets of plain paper, reducing the frequency of refills. A multi-purpose tray supports up to 50 sheets, ideal for envelopes, labels, and thicker paper stocks. Supported paper sizes include Letter, Legal, Executive, A4, A5, A6, and B5, providing flexibility for various document formats.

The printer also features automatic duplex printing, enabling convenient two-sided printing to conserve paper and reduce costs; Maximum paper capacity, including the multi-purpose tray, reaches 300 sheets. The MFC-2700DW handles paper weights from 17 lb to 43 lb, ensuring compatibility with diverse paper qualities. Its robust paper handling system minimizes paper jams and ensures reliable performance, even with high-volume printing tasks. This capability makes it suitable for both home and office environments.

Connectivity Options

The Brother MFC-2700DW boasts a comprehensive suite of connectivity options, designed for seamless integration into diverse network environments. It features built-in 802.11b/g/n Wi-Fi for wireless printing and scanning, eliminating the need for cables. Ethernet connectivity provides a stable wired network connection for enhanced reliability. Furthermore, it includes a Hi-Speed USB 2.0 interface for direct connection to a computer.

Mobile printing is supported through Brother iPrint&Scan, allowing users to print and scan directly from smartphones and tablets. Compatibility extends to AirPrint, Google Cloud Print, and Mopria, offering versatile mobile printing solutions. The MFC-2700DW also supports network scanning, enabling multiple users to share the scanner. These diverse connectivity options ensure flexibility and convenience, catering to various user preferences and network configurations, making it a versatile addition to any workspace.

Dimensions and Weight

Understanding the physical specifications of the Brother MFC-2700DW is crucial for placement and logistical considerations. The machine’s dimensions are approximately 17.2 inches (W) x 15.7 inches (D) x 11.8 inches (H). These measurements are vital when determining suitable locations within an office or home environment, ensuring adequate space for operation and access.

The MFC-2700DW weighs approximately 22.5 pounds (10.2 kg). This weight is important for transportation and installation purposes. It’s substantial enough to provide stability during operation, yet manageable for relocation when necessary. Considering both the dimensions and weight allows for proper planning, preventing potential issues related to space constraints or lifting limitations. Accurate knowledge of these physical attributes contributes to a smooth and efficient user experience.